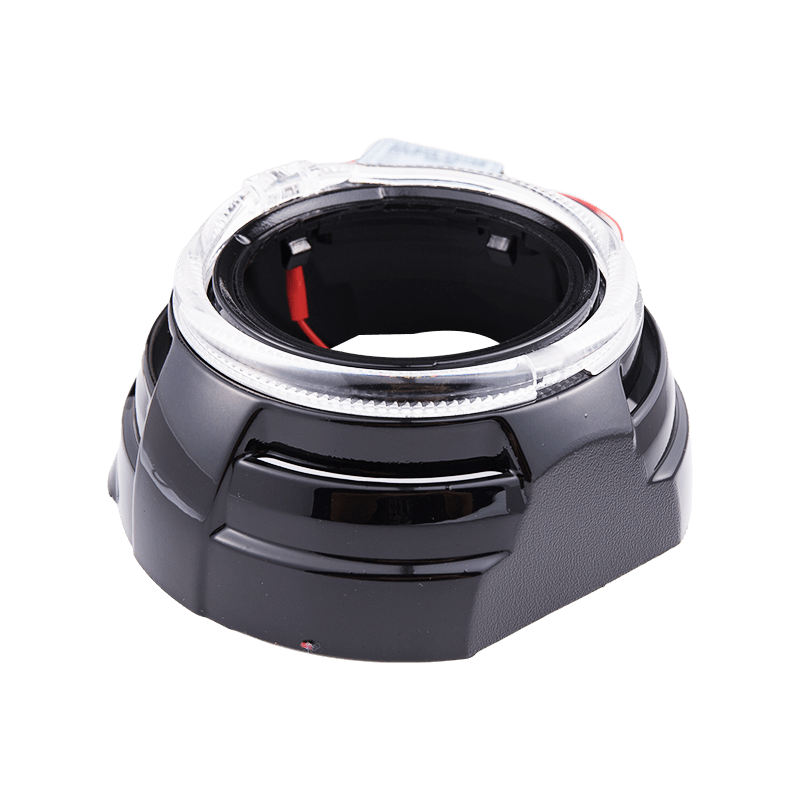

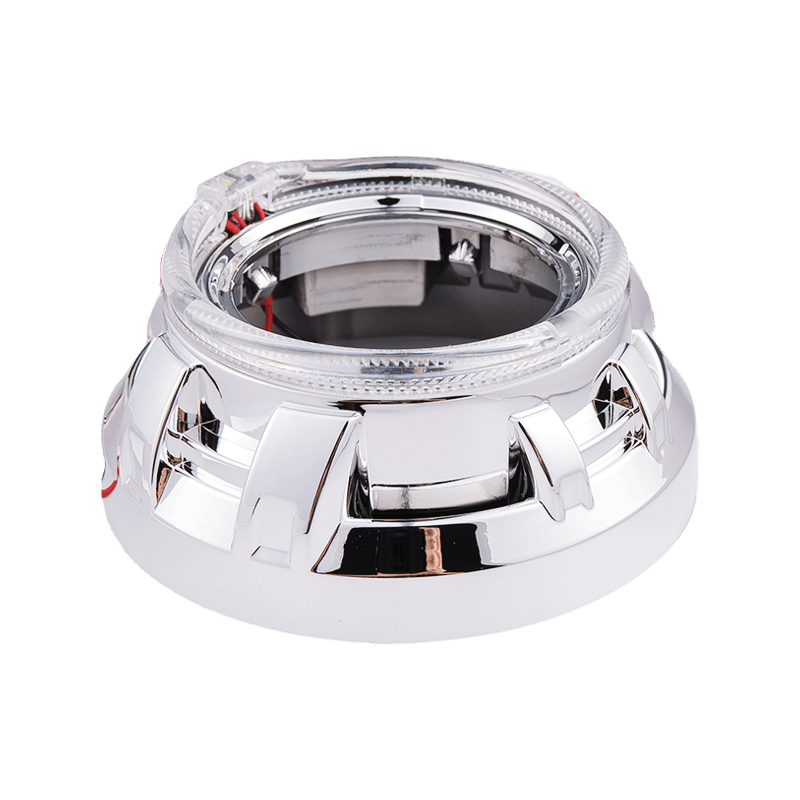

In the automotive industry, car lights are not only an indispensable safety guarantee for night driving, but also an important display of vehicle personalization and aesthetic design. Car angel eye lampshades, with their unique halo design and elegant appearance, have become iconic elements in modern automotive design. However, behind these eye-catching lampshades, there are complex manufacturing processes and sophisticated surface treatment technologies. Among them, primer, as a key component of the surface coating, is of great importance.

In the production process of car angel eye lampshades, primer plays a vital role. The surface of the lampshade may have problems such as unevenness, scratches or defects due to injection molding or electroplating processes. These problems not only affect the aesthetics of the lampshade, but also have an adverse effect on the subsequent varnish coating, resulting in uneven coating, reduced gloss or obvious defects. Therefore, the primary task of the primer is to fill these unevenness and defects and provide a uniform and flat base for the coating of the varnish.

The filling performance of the primer is mainly due to its unique formula and process. Primers usually contain fine pigment particles and fillers that penetrate into the tiny pores and scratches on the surface of the lampshade to form a solid filler layer. This filler layer can be further flattened through proper sanding and polishing to create ideal conditions for the application of clearcoat.

In addition to providing a uniform base, primers also play the important role of enhancing the adhesion between the coating and the lampshade substrate. The lampshade substrate may be plastic, metal or other composite materials, and the surface properties of these materials vary, and the adhesion requirements of the coating are also different. The primer can penetrate the surface of the substrate and form chemical bonds or physical adsorption, which significantly improves the bonding between the coating and the substrate. This enhanced adhesion not only helps prevent the coating from falling off or flaking during use, but also improves the durability of the entire coating.

Primers also provide additional protection for the lampshade. Before the clearcoat is applied, the primer can form a dense protective film to block the harmful factors such as moisture, oxygen and ultraviolet rays in the external environment from eroding the lampshade substrate. This protective effect not only extends the life of the lampshade, but also maintains its original gloss and color.

In the surface coating of the car angel eye lampshade, the synergy of primer and clearcoat is crucial. The primer provides a flat and uniform base for the clearcoat, ensuring that the clearcoat can be evenly and smoothly applied to the surface of the lampshade. This uniform coating not only improves the gloss and color saturation of the lampshade, but also makes it present a smoother and brighter appearance.

The filling performance and adhesion enhancement of the primer also provide a solid foundation for the coating of the clearcoat. The primer can fill the unevenness and defects on the surface of the lampshade, so that the clearcoat can be more evenly distributed on the surface of the lampshade when applied. In addition, the enhanced adhesion of the primer also helps to improve the bonding between the clearcoat and the lampshade substrate, thereby ensuring the stability and durability of the entire coating.

In the production process of the car angel eye lampshade, the selection of primer and process optimization are crucial to ensure the quality of the coating. Manufacturers need to choose the right type of primer according to the material of the lampshade, the use environment and the specific needs of the customer. For example, for plastic lampshades, you may need to choose a primer with good adhesion and flexibility; while for metal lampshades, you may need to choose a primer with excellent corrosion resistance and filling properties.

In addition, the coating process of the primer also needs to be strictly controlled. Before coating, the surface of the lampshade needs to be thoroughly cleaned and treated to remove impurities such as oil, dust, etc. During coating, the thickness and uniformity of the coating need to be controlled to avoid defects such as bubbles and sagging. After coating, proper drying and curing treatment is also required to ensure that the primer can be fully cured and form a solid protective film.

In the actual production process of automotive angel eye lampshades, the application of primer also faces some challenges. For example, the complex shape and details of the lampshade surface may increase the difficulty of primer coating. In order to meet these challenges, manufacturers need to adopt advanced coating technologies and equipment, such as robotic spraying systems, high-pressure airless spraying, etc., to ensure that the primer can be evenly and accurately coated on the surface of the lampshade.

The compatibility between primer and clearcoat is also a problem that needs attention. There may be chemical reactions or incompatibility between different primers and varnishes, which may cause defects such as delamination and peeling of the coating. Therefore, when selecting primers and varnishes, sufficient compatibility testing is required to ensure that they can match each other and form a good coating system.

Primer plays a vital role in the surface coating of the car angel eye lampshade. It not only provides a flat and uniform base for the varnish, but also enhances the adhesion between the coating and the lampshade substrate and provides additional protection for the lampshade. By reasonably selecting the type of primer and strictly controlling the coating process, it can be ensured that the surface coating of the car angel eye lampshade has excellent gloss, color saturation and durability. With the continuous advancement of science and technology and the continuous optimization of technology, we have reason to believe that the future car angel eye lampshade will be more outstanding and inject new vitality into the development of the automotive manufacturing industry.

English

English Español

Español عربى

عربى русский

русский