On the dazzling stage of LED lighting technology, single-beam LED headlight bulbs have become a powerful assistant for outdoor explorers, professional maintenance personnel and medical workers with their unique optical properties and wide application fields. Behind this bright pearl, precision dispensing technology is like an invisible patron saint, silently escorting the performance and life of LED headlight bulbs.

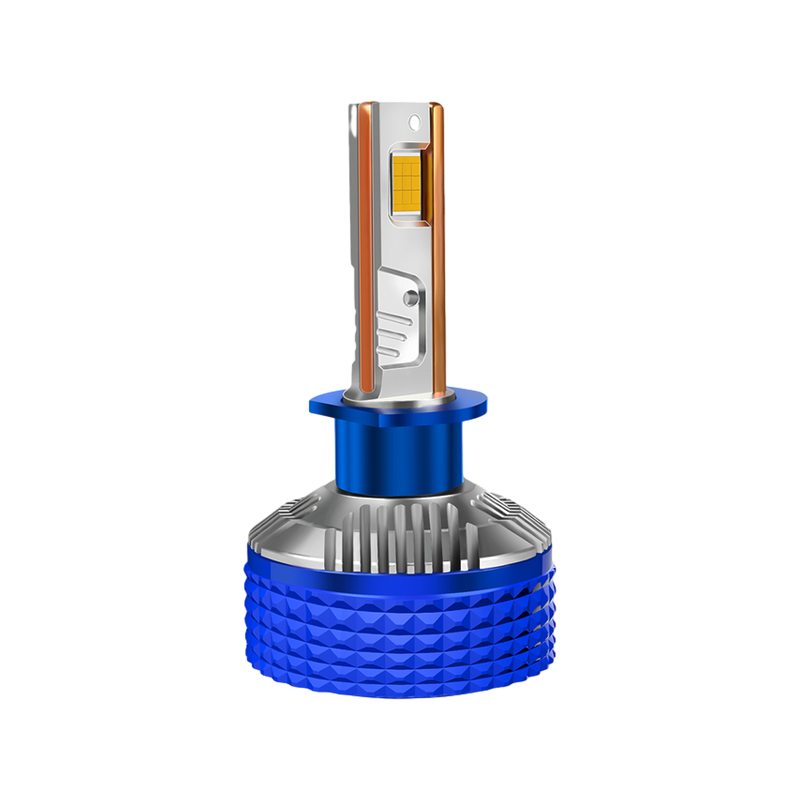

In the manufacturing process of LED headlights, dispensing technology is a crucial link. This technology uses high-precision equipment to evenly coat the key material of epoxy resin on the LED chip and its welding wire with extremely small amounts and extremely high precision. This process seems simple, but it actually contains extremely high technical difficulty and process requirements. The uniformity of dispensing, position accuracy and material selection will directly affect the final performance of LED headlights.

The epoxy resin protective layer formed by precision dispensing technology is the first line of defense for LED headlight bulbs against external invasion. This solid and transparent protective layer, like a loyal guard, isolates the LED chip from the outside air and moisture, effectively preventing the chip from being damaged by oxidation and corrosion. At the same time, the existence of this protective layer also greatly improves the light extraction efficiency, allowing the light emitted by the LED to illuminate the target area more brightly and evenly, bringing users a clearer and more comfortable visual experience.

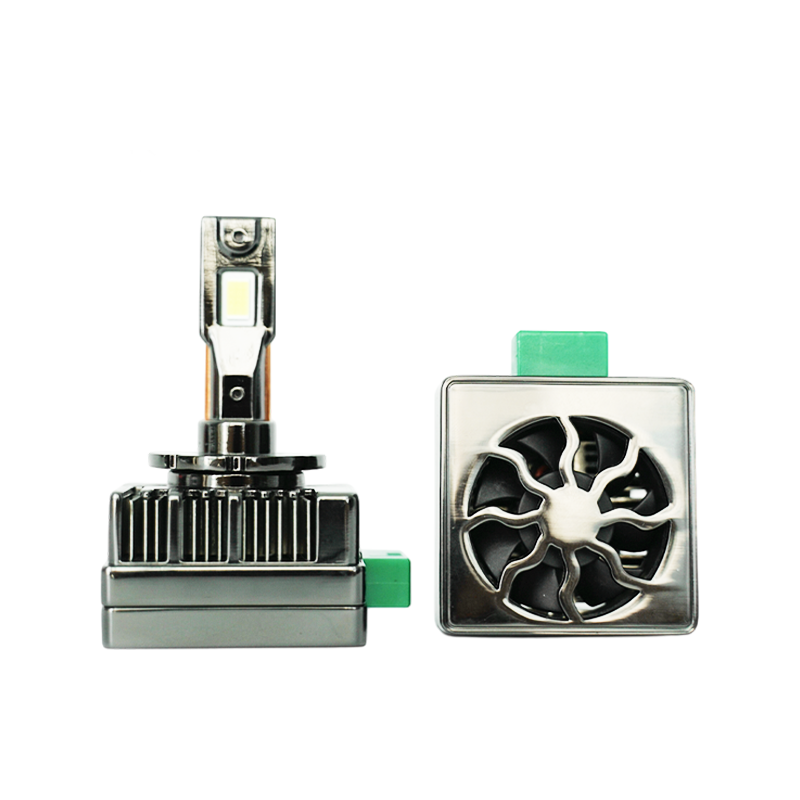

In addition to the protective function, epoxy resin also has certain heat dissipation properties. LEDs will generate a certain amount of heat during operation. If the heat cannot be dissipated in time, it will cause the LED temperature to rise, thereby affecting its performance and life. The existence of the epoxy resin protective layer provides a good heat dissipation channel for LEDs. It can quickly transfer the heat generated by the LED when it is working to the radiator or other heat dissipation structure, keeping the LED chip running at a lower temperature, thereby ensuring the stability and reliability of the headlights.

The application of precision dispensing technology not only improves the performance and life of single-beam LED headlight bulbs, but also provides strong support for its wide application in various fields. In outdoor adventures, high-brightness, uniform light beams can illuminate the road ahead and provide safe lighting for explorers; in medical examinations, precise light beam control can help doctors observe the patient's lesions more clearly; in industrial maintenance, stable lighting performance can improve maintenance efficiency and ensure the normal operation of equipment.

As a key link in the manufacturing process of single-beam LED headlight bulbs, precision dispensing technology provides a solid guarantee for the performance and life of LED headlights with its precise, uniform operation and multi-functional protective layer. With the continuous advancement and innovation of technology, we have reason to believe that the future precision dispensing technology will be more intelligent and efficient, bringing more surprises and breakthroughs to the field of LED lighting. Single-beam LED headlight bulbs will also show their unique charm in more fields and become a shining star that illuminates our lives and work.

English

English Español

Español عربى

عربى русский

русский