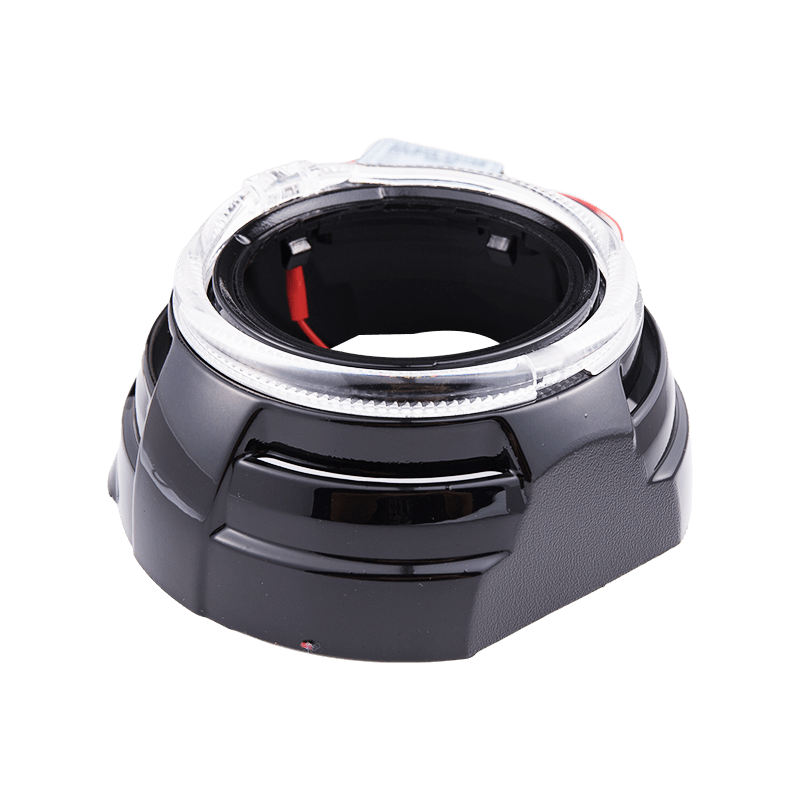

The reflector is one of the core components of LED headlights. Its main function is to reflect and focus the light emitted by the LED light source onto the road ahead, ensuring that the driver has sufficient vision and clear lighting effects. However, ordinary reflector surfaces often have problems such as low reflectivity and light scattering, resulting in low light utilization and poor lighting effects. To solve this problem, manufacturers use aluminum plating to treat the surface of the mirror.

Aluminum coating is a protective layer formed by depositing a thin layer of aluminum film on the surface of the reflector. This layer of aluminum film not only has an extremely high reflectivity, able to reflect almost all the light emitted by the LED light source to the predetermined direction, but also can effectively reduce the scattering and loss of light, thereby significantly improving the lighting effect. According to experimental data, the reflectivity of the reflector that has been aluminum-plated can be as high as over 90%, which is much higher than that of the untreated reflector. This means that under the same LED light source, the aluminum-plated reflector can direct more light to the road ahead, providing the driver with a brighter and clearer lighting environment.

In addition to improving reflectivity, the aluminum coating also has excellent protective properties. In LED headlights, the light emitted by the LED light source contains not only visible light, but also ultraviolet rays and other harmful radiation. If these harmful radiations directly irradiate the reflector substrate, it will cause the substrate to age, fade, or even crack, which will seriously affect the lighting effect and service life of the bulb.

However, the presence of the aluminum coating acts like a solid barrier that can effectively block the invasion of these harmful radiations. Aluminum, as a metal with excellent conductivity and reflectivity, can absorb and reflect most of the ultraviolet rays and other harmful radiation, thus protecting the reflector substrate from corrosion. This not only extends the service life of the reflector, but also ensures the stability of the overall performance of the lamp.

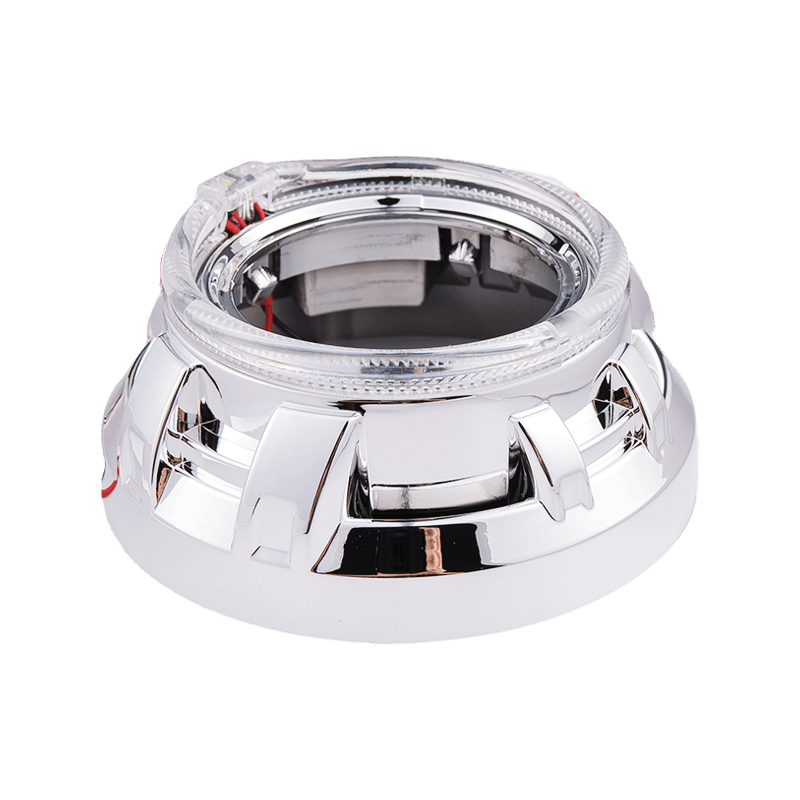

In addition to the above two advantages, the aluminum coating can also improve the appearance texture of the bulb to a certain extent. The aluminum-plated reflector surface presents a bright and dazzling metallic luster, which not only increases the visual effect of the bulb, but also makes it look more high-end and atmospheric. This improvement in appearance not only meets consumers' demand for aesthetics, but also enhances the overall competitiveness of the product.

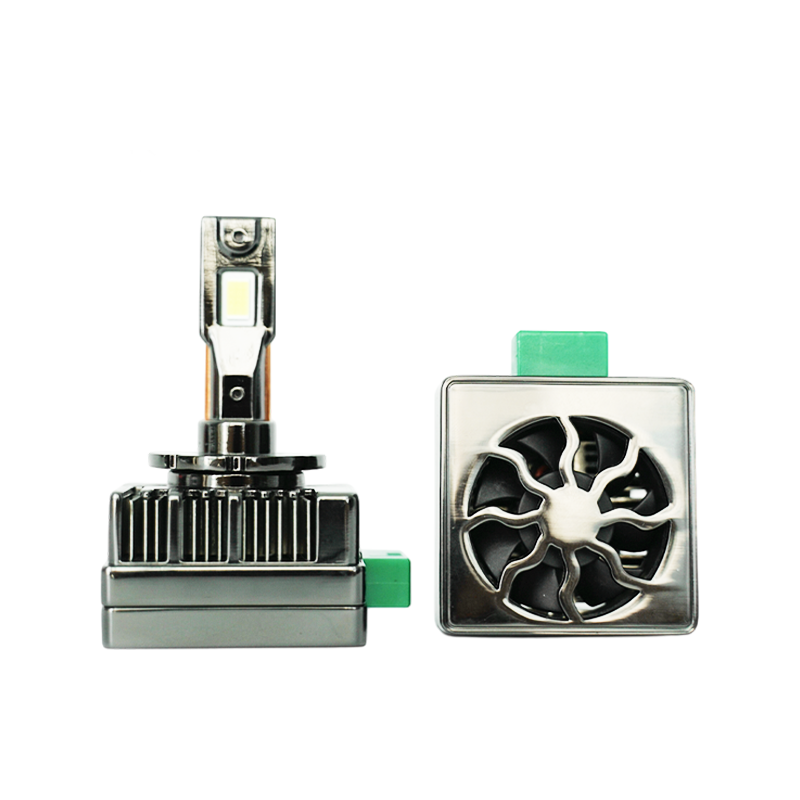

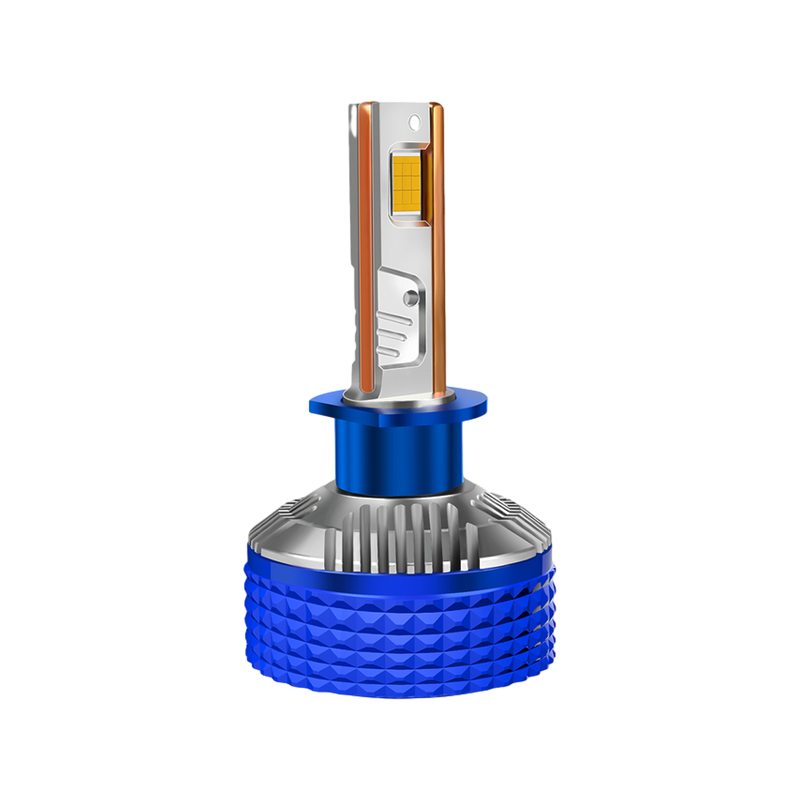

Aluminum plating technology is widely used in H1, H3, H4, H7, H11 and R11 35W LED headlight bulbs. These bulbs not only use high-performance LED light sources and optimized optical design, but also further enhance the performance of the reflector through aluminum plating. This makes these bulbs excel in lighting effect, service life and appearance texture.

Take the H7 model as an example. This type of bulb is usually used as a low beam or high beam. In low beam mode, the aluminum reflector can evenly project the light from the LED light source onto the road ahead, providing the driver with a clear view; in high beam mode, the aluminum reflector can focus the light more The light is projected far into the distance, ensuring that the driver has sufficient lighting distance at night or in bad weather conditions.

Likewise, the H11 model bulbs also use aluminized reflector technology. This type of bulb is usually used as fog lamp or daytime running lamp. In adverse weather conditions such as fog or rain, the aluminum reflector ensures that the light penetrates the fog while maintaining sufficient brightness, providing the driver with a clear view; in daytime driving mode, the aluminum reflector It can ensure that the light is softer and more uniform, avoiding interference to other road users.

With the advancement of science and technology and the continuous improvement of consumers' requirements for product performance, aluminum coating technology is also constantly innovating and developing. In the future, aluminum coating technology will pay more attention to improving environmental protection, durability and intelligence. For example, more environmentally friendly aluminum plating materials and processes are used to reduce the impact on the environment; the reflectivity and protection performance are further improved by optimizing the structure and performance of the aluminum plating layer; and the intelligent control system is combined to achieve precise adjustment of the direction and intensity of light. wait.

In addition, with the continuous advancement of LED technology and the reduction of costs, H1/H3/H4/H7/H11 R11 35W LED headlight bulb will become more popular in the future, and the application of aluminum coating technology will also become more extensive. This will bring consumers a better quality and more efficient lighting experience, and will also drive the automotive lighting industry towards a more intelligent and environmentally friendly direction.

English

English Español

Español عربى

عربى русский

русский